SRI01 PTFE Coating

Oilless bearing or low-oil-content lubrication is applied to the conditions where is impossible or difficult to be lubricated. Maintenance free and reliable operation avoids risk of insufficient oils lubricating.

Products

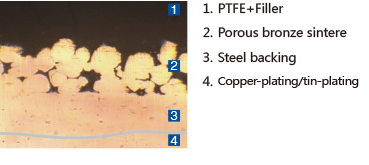

Metal-polymer self-lubricating composite materials consist of metal backing sintered porous bronze with PTFE polymer as working layer. The metal backing provides mechanical strength, while the bronze sintered layer provides a strong mechanical bonding between the backing and the bearing lining, the PTFE polymer offers exceptional low friction even under dry condition and the thermoplastic polymer is generally designed to operate with marginal lubrication. The construction promotes dimensional stability and improves the thermal conductivity. This material meets the demands for longevity, speed and temperature criteria with or without lubrication.

Oilless Elements

SRI02 IS TRIPLE-LAYER SELF LUBRICATING MATERIAL THAT CAN FILI MODIFIED POM PLASTIC AS SU RFACE LAYER; IT IS BENIGNANT BOUNDARY ...

CASTING BRONZE BEARING PLUGGED WITH GRAPHITE, ROHS STANDARD, NO WASTE OIL RECYCLING IS ENVIRONMENTALLY FRIENDLY.

Applications

Agricultural machinery: tractors, combine harvesters, crop sprayers, bulldozers, graders, etc.

Automotive industry: power steering pump, steering gear thrust washers, disc brakes, shock absorbers, hinges, wiper, chair recliners, air valves and solenoid valves, etc.;

Business machines: duplicator, fax machine, automatic printing devices, mail processing machinery...

Hydraulics and valves: pumps including gear, rotary, water, axial piston, and other types, ball, butterfly, poppet steam, and other valves and valve trunnions...

Home appliances: tape recorders, refrigerators, air conditioners, cleaners, polishers, sewing machines, ovens, dishwashers, clothes washing machines...

And materials handling, marine engine, packaging, textile equipment, tools...etc.

Material Structure

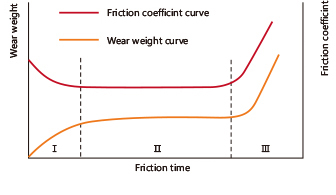

Wear-resisting Performance

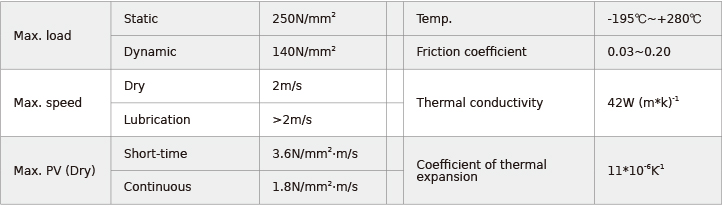

Factor

Technology

Note: Various materials are suitable for SRI01 Series products according to different working conditions, such as bronze backing (SRI01B), stainless steel backing (SRI01S) and lead-free material (SRI01W).

1. "Running-in" phrase: PTFE compound on the bushing is transferred to its mating surface and forms a lubricating film. At this phase,the friction coefficient is bigger, thus the abrasion pace is very quick. See the curve showed in area I of the graph.

2. "Stabilization" abrasion phrase: After the "Running-in

phase", the friction happens between PTFE and PTFE, thus the friction coefficient is smaller and keeps steady. As a result, the wear rate is low and steady. See the curve showed in areaⅡof the graph.

3. "Sharp" abrasion phrase: As PTFE in the porous layer is slowly consumed up, not enough lubricant can be supplied to the gliding media. Friction coefficient and wear rate will rapidly rise. When 70% of the bronze surface is exposed, service life of SRI01 closes to its end. See the curve showed in area Ⅲof the graph.

SRI01 is of excellent anti-abrasion performance,mainly due to the particular molecule structure of PTFE. The abrasion process can be generally divided into three phases, so there kinds of friction coefficient. See the right graph:

1). PV Value

PV value is an effective criterion to calculate the service life of BKL-1. If there is need to prolong the service Life, PV value must be reduced.

2). Ambient Temperature

The higher the working temperature is, the shorter the life of the products would be.

3). Quality of the Mating Surface

Service life BKL-1 can be obviously prolonged if its mating axis is made by alloy steel or is plated by hard chrome and with surface Roughness Ra=0.4~0.63

Besides the standard products displayed in the list of this catalogue. We can also supply non-standard products or develop according to customer design.

Contact

Office:1210/8 No.999 Dongxiu Rd. Pudong Shanghai 200127 China

Manufacturing:Ganyao Industrials Park, Jiashan, Zhejiang, China

PH: +86 21 68458332

FAX: +86 21 68459338

Email: info@rotationparts.com

Http://www.rotationparts.com

Copyright © SRI BEARINGS All rights reserved